The manufacturing journey of high-tech eco translucent sandwich panels

The story of our eco translucent sandwich panels begins with innovation, sustainability, and a commitment to creating solutions that redefine modern architectural design.

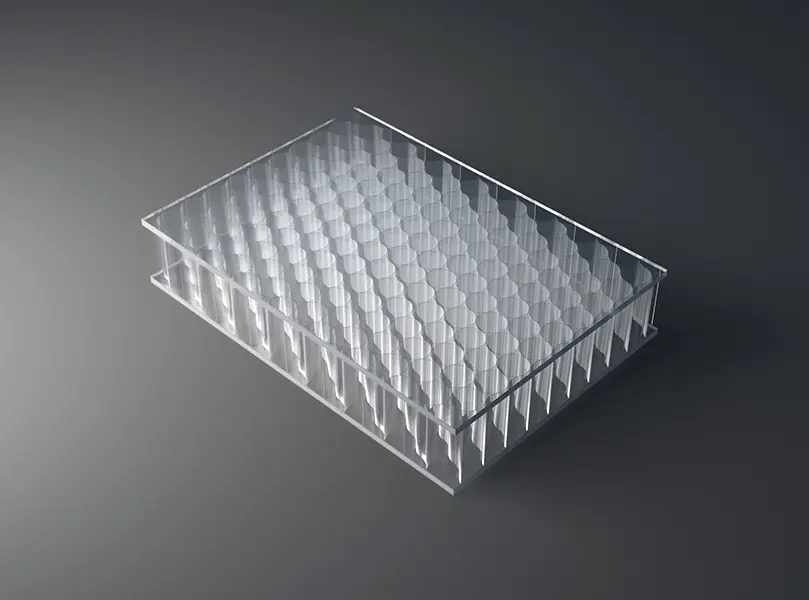

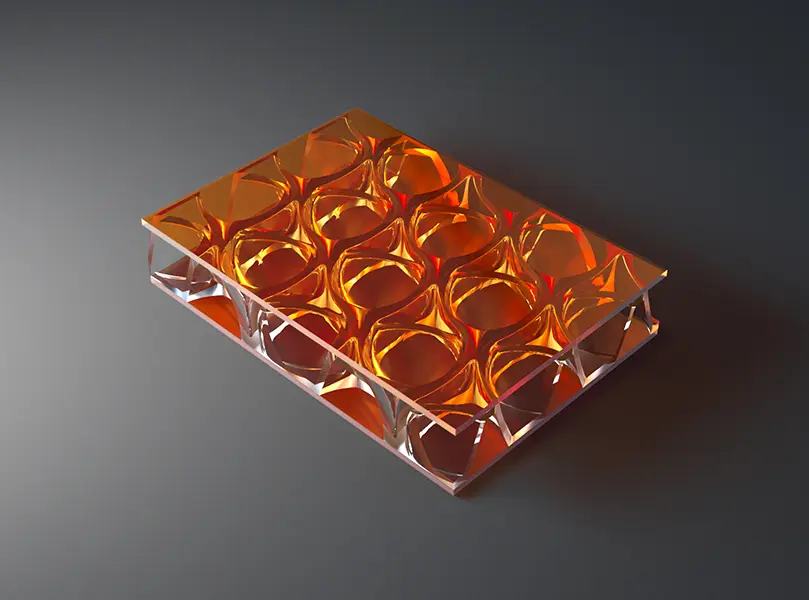

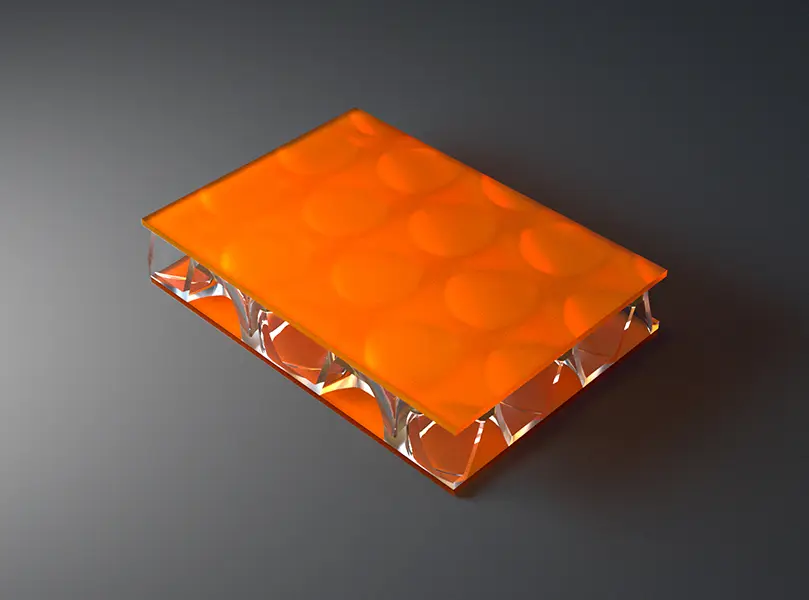

At Design Composite, the focus is on crafting lightweight, translucent panels such as clear-PEP®, AIR-board®, AIR-board® acoustic, and AIR-board® acoustic quiet, which are ideal for both interior and exterior applications. These panels combine advanced technology with eco-friendly practices to deliver stunning aesthetics and exceptional functionality.

Discover the manufacturing process

For a closer look at how these eco translucent sandwich panels come to life, we invite you to watch a video featuring Hans Aster, the site manager. The video showcases the advanced manufacturing techniques, the role of Felder Group’s CNC machines, and the sustainable practices that define Design Composite’s operations.

The journey of creating eco translucent sandwich panels is one of innovation, sustainability, and attention to detail. By combining advanced materials, cutting-edge technology, and environmentally friendly practices, Design Composite delivers panels like clear-PEP®, AIR-board®, AIR-board® acoustic, and AIR-board® acoustic quiet that transform architectural design. Whether you’re looking for translucent facades or acoustic interior solutions, these panels offer the perfect balance of functionality and aesthetics.

Watch the video to learn more about the innovative manufacturing process and explore how these panels can elevate your next architectural project.

A Legacy of Innovation in Architectural Design

For over 25 years, Design Composite has specialized in producing eco translucent sandwich panels that enhance architectural projects worldwide. From iconic facades in New York to creative interior partitions in Australia, their panels offer a blend of performance, durability, and visual appeal. What sets these panels apart is the meticulous manufacturing process and a commitment to sustainability embedded in every step.

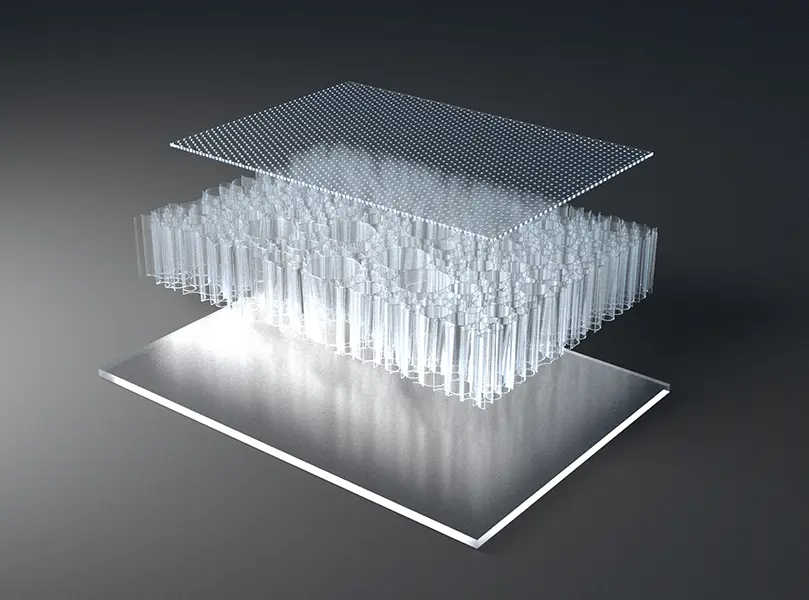

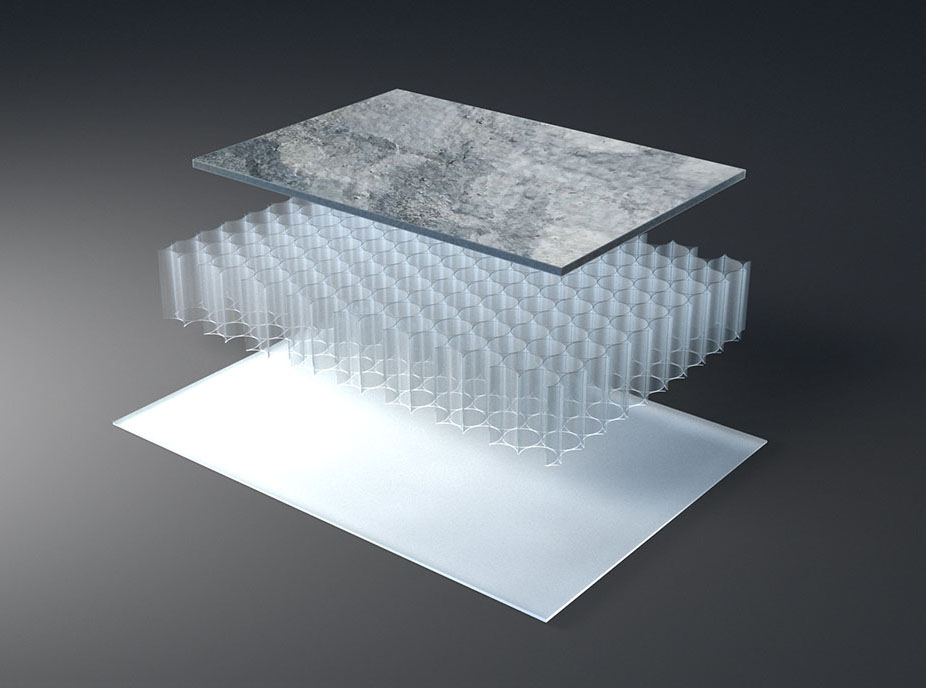

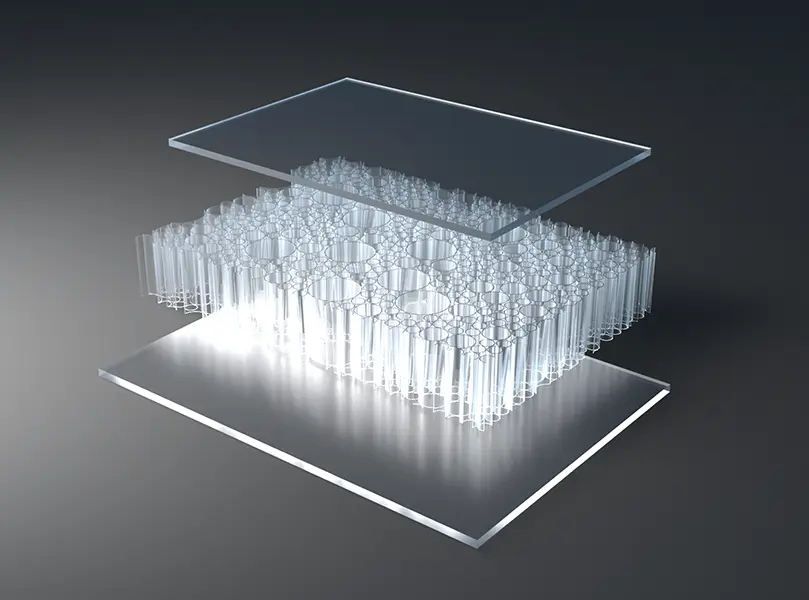

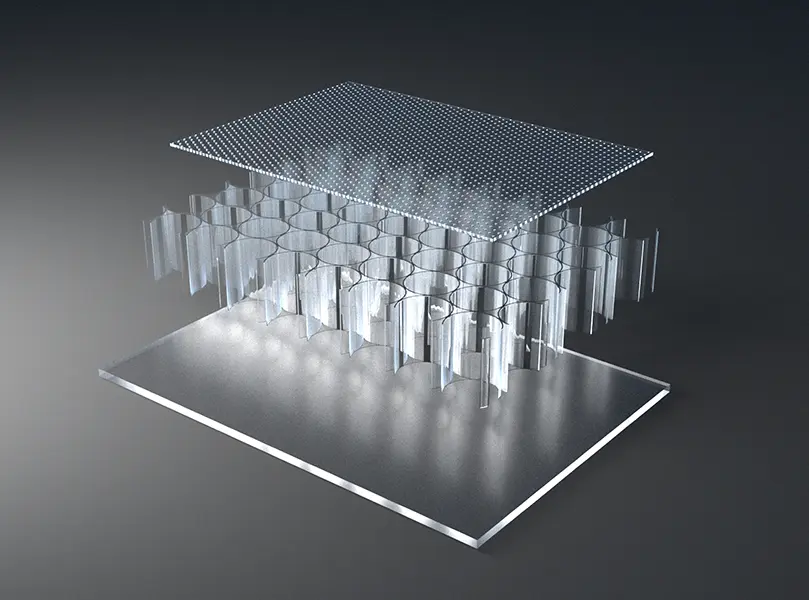

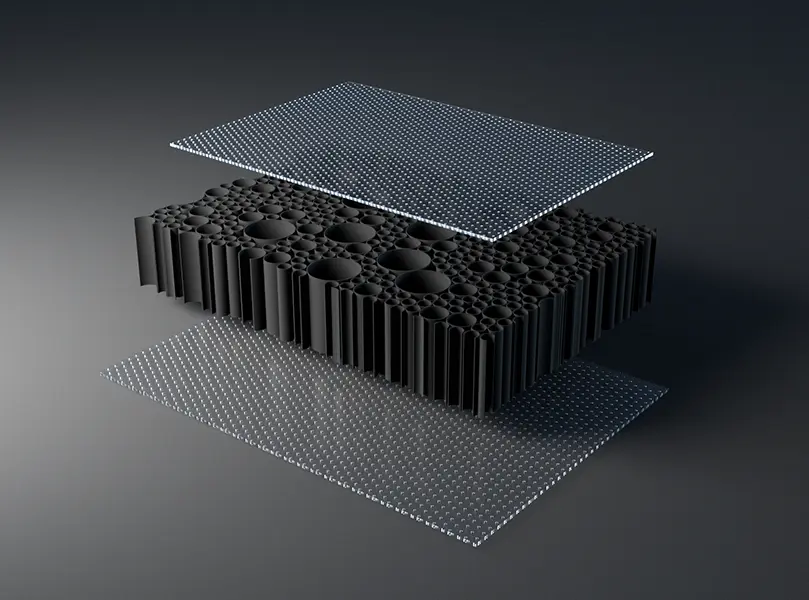

The company’s expertise lies in bonding advanced materials to create unique sandwich elements, such as translucent architectural thermoplastic panels. This includes the clear-PEP® series, known for its high strength and elegant translucency, and the AIR-board® acoustic range, which combines sound absorption with the ability to let light flow naturally through spaces.

Behind the scenes: manufacturing eco translucent sandwich panels

The journey of crafting eco translucent sandwich panels begins with understanding the needs of architects and designers. Every project starts with collaboration to identify key performance and design requirements, whether it’s a visually striking facade, a functional partition, or a translucent ceiling that enhances natural light.

Design Composite’s facility in Austria employs cutting-edge CNC machines from the Felder Group. These machines ensure the precision required to produce panels with intricate patterns, perfect cuts, and flawless finishes. According to site manager Hans Aster, the reliability and support provided by Felder Group have been instrumental in maintaining production efficiency and quality.

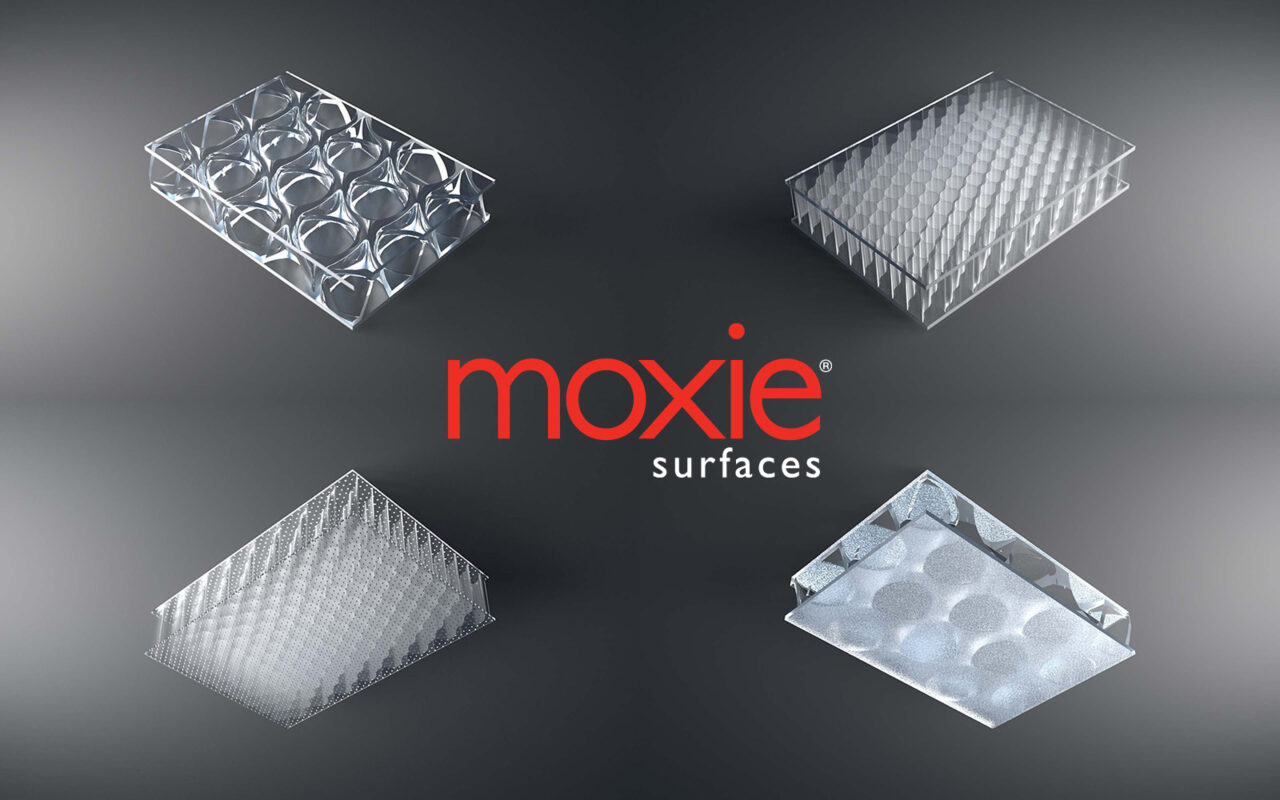

The clear-PEP® and AIR-board® panels are manufactured using thermoplastic cores and lightweight facing sheets. This allows for high flexibility in design while ensuring the durability needed for architectural applications. Whether it’s the AIR-board® acoustic quiet panels used for reducing noise in modular indoor spaces or clear-PEP® panels that create translucent facades, every product reflects a commitment to quality and innovation.

Sustainability at the core of production

Sustainability is a cornerstone of Design Composite’s philosophy. The production of eco translucent sandwich panels incorporates environmentally responsible practices to minimize waste and optimize energy use. Some key initiatives include:

- Recycling and Repurposing: Returned panels are recycled into new products, ensuring a sustainable lifecycle.

- Heat Recovery Systems: Thermal energy is reused for underfloor heating and preheating air in ventilation systems.

- Facility Optimization: The manufacturing site maximizes passive solar energy and uses superior insulation to reduce energy consumption.

These efforts result in significant CO₂ emission reductions, further solidifying their commitment to eco-friendly manufacturing.

Panels that redefine architectural possibilities

Design Composite’s range of eco translucent sandwich panels offers limitless possibilities for architectural innovation. The clear-PEP® panels, with their sleek, translucent appearance, are perfect for facades, skylights, and partitions that require both visual appeal and functionality. The AIR-board® range, including the acoustic and acoustic quiet options, provides sound absorption and light diffusion, making them ideal for interior applications such as office partitions and modular designs.

Whether used in hotel lobbies, walkways, or self-service car wash facilities, these panels offer a unique combination of strength, durability, and design flexibility. Their ability to transmit natural light while maintaining insulation adds a layer of sophistication to any project.

Having a strong connection with you, our customers, is vital to our business, as it will help us with shaping our future products and services. Because of this, we encourage you to use our Contact page in order to share your thoughts on the samples you received, as well as whether or not you would utilise our panels in your future projects.