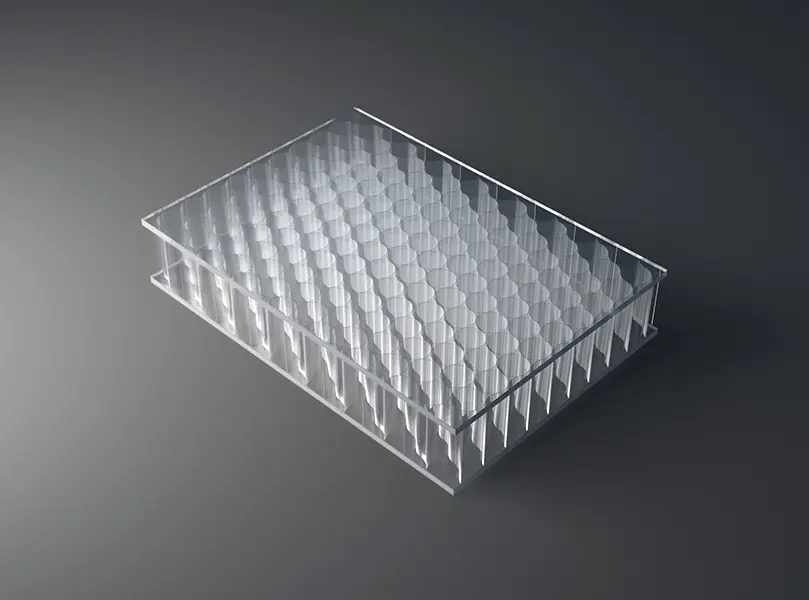

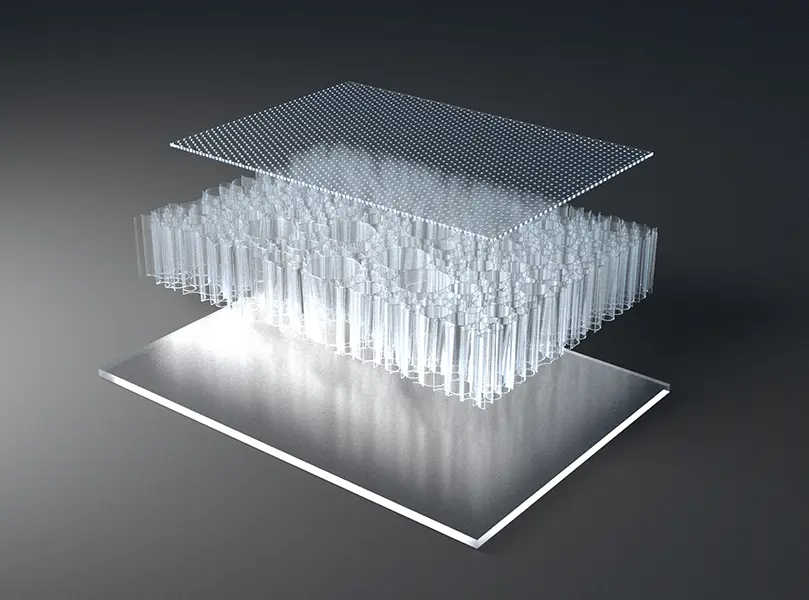

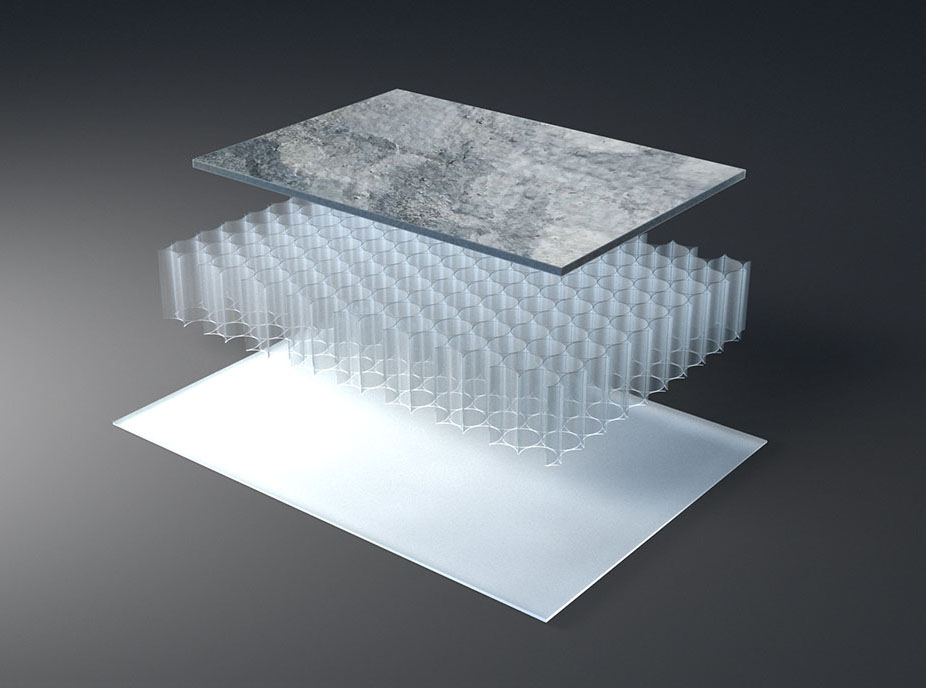

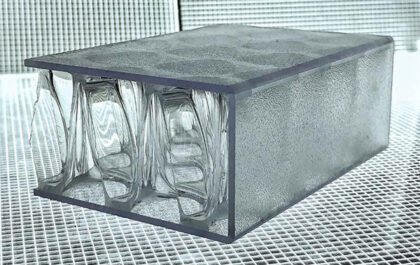

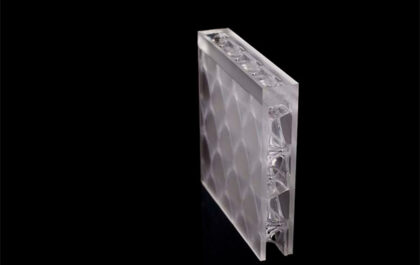

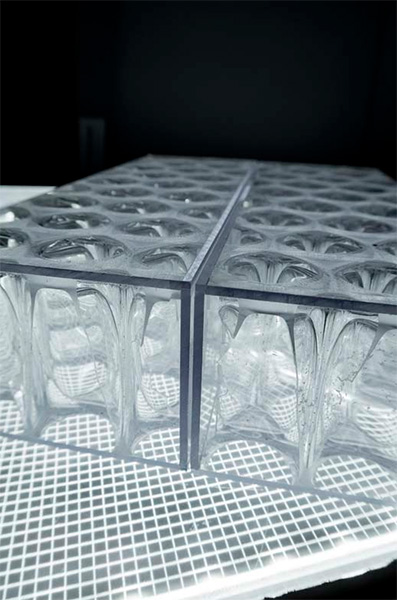

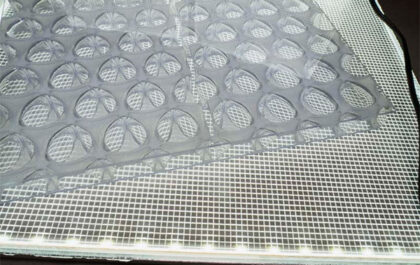

The elements made of high-quality thermoplastics can be used in many different ways in interior architecture and can be designed individually in colour and shape. Newly developed profile systems allow creative applications and exciting possibilities to be designed. Check below all the available addons for clear-PEP and AIR-board panels that suit the needs of your project.

interior / exterior edge finish

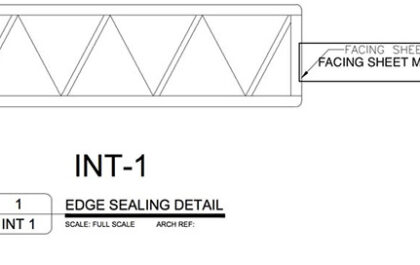

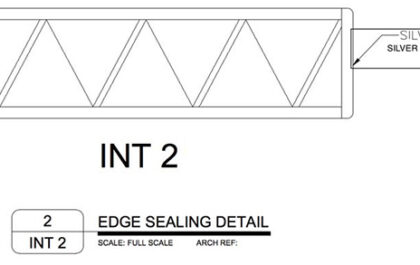

interior edge finish 1

interior edge finish 2

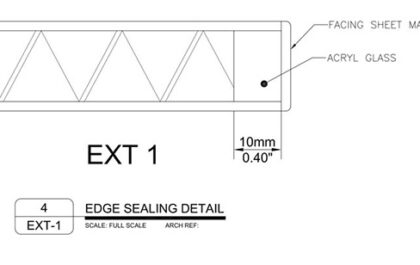

exterior edge finish 1

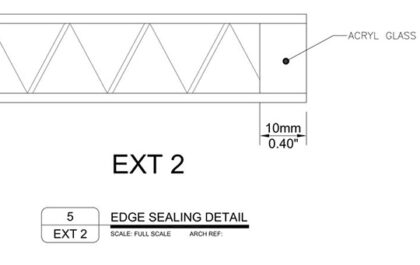

exterior edge finish 2

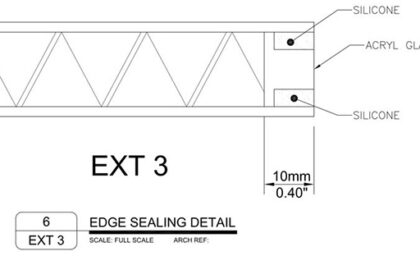

exterior edge finish 3

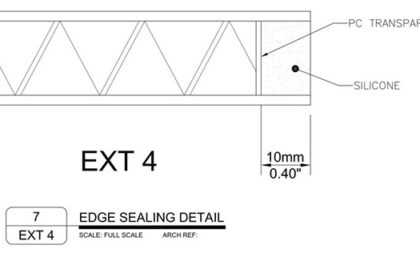

exterior edge finish 4

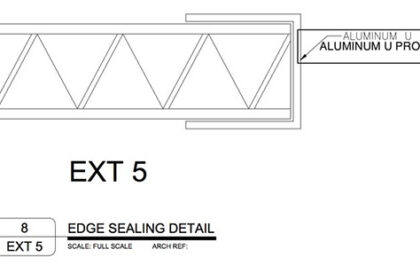

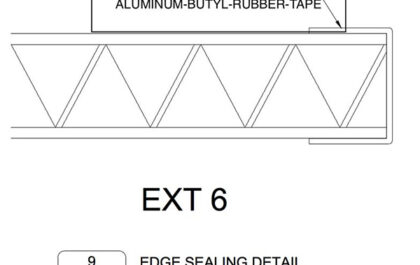

exterior edge finish 5

exterior edge finish 6

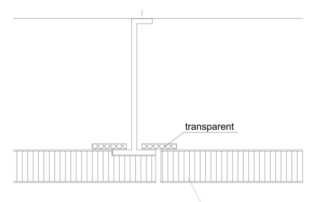

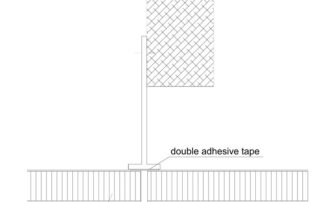

panel joints & connections

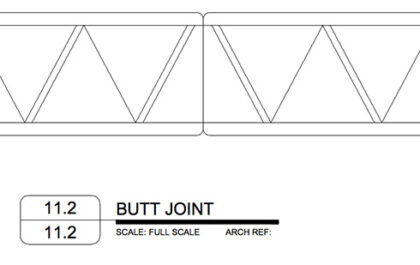

Butt joint

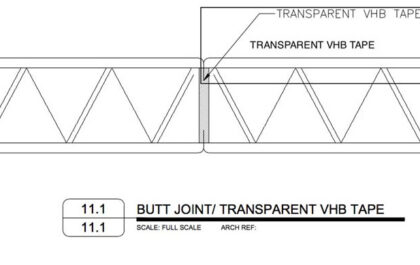

Butt Joint VHB Tape

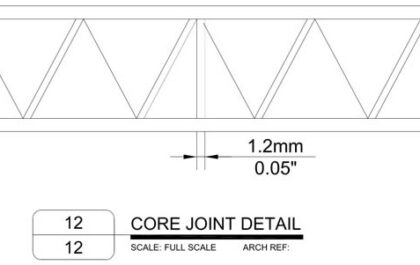

Core Joint

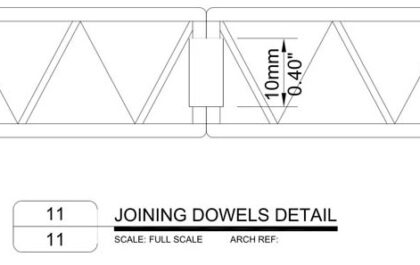

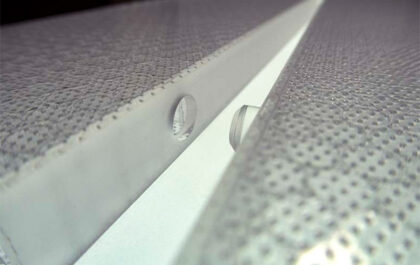

Dowel Connection

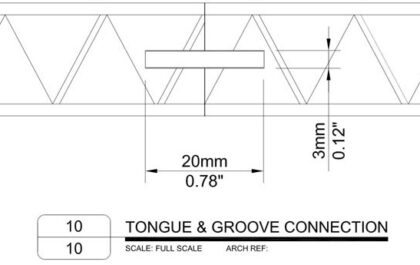

Tongue & Groove

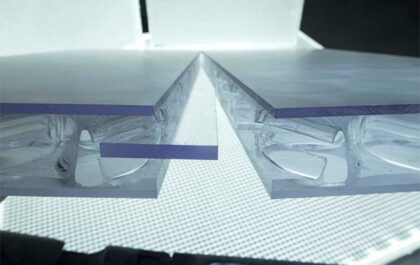

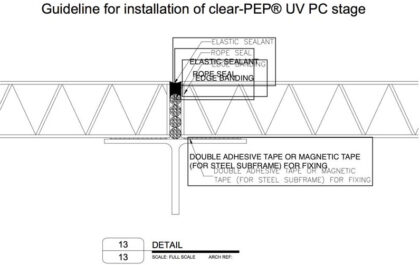

clear-PEP® Stage flooring

fabrication

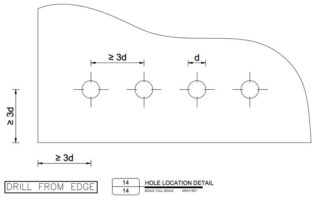

Drilling and Hole Locations

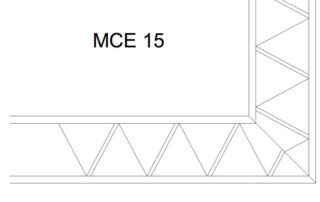

Mitre Edge

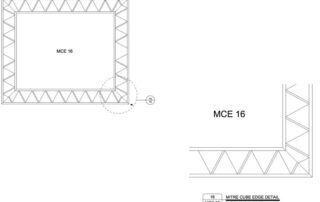

Mitre Cube Edge

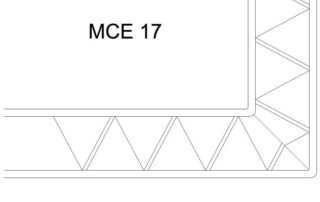

Mitre Fold Edge

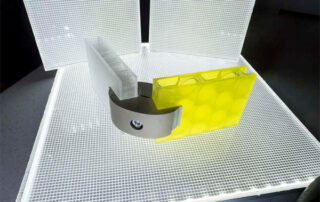

Heat Forming / Bending

Our panels can be heat formed in molds using the following design guidelines

| clear-PEP + satin facing sheets* |

|---|

| Maximum thickness is 19 mm or 3/4″ |

| Min. bending radius: 1000 mm or 39″ |

| Max. panel size: 3020×1220 mm / 118″ x 48″ |

* We recommend to use satined surfaces because on glossy surfaces uneveness which can occur in bending process is likely to be visible.

| AIR-board Acoustic |

|---|

| Max. thickness:25mm / 1″ |

| Min. bending radius: 300 mm / 12″ |

| Max. panel size: 3020×1500 mm / 118″ x 59″ |

Panels that cannot be thermally formed the following method can be used

| Forming with mitre cuts on reverse |

|---|

| Min. distance between cuts: 50 mm / 1.9″ |

| Min. facing sheet thickness: 2 mm / 0.08″ |

mechanical connection

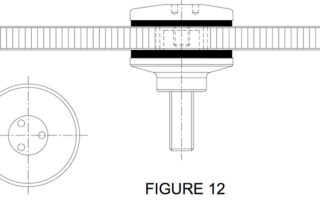

Glazing Fastener

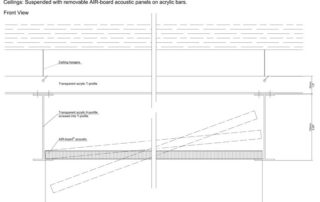

ceiling connections

ceiling connection 1.2

ceiling connection 7

ceiling connection 11

![]()