clear-PEP® ECO PC stage

REQUEST SAMPLES

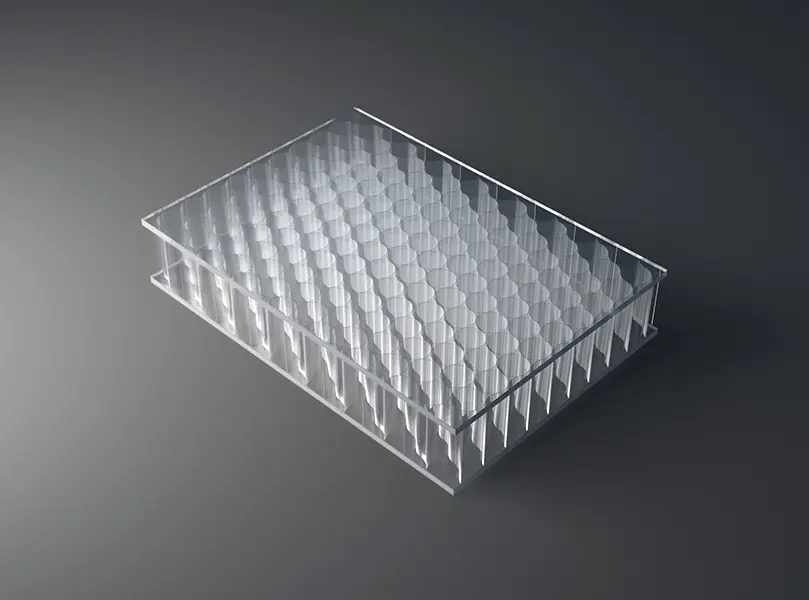

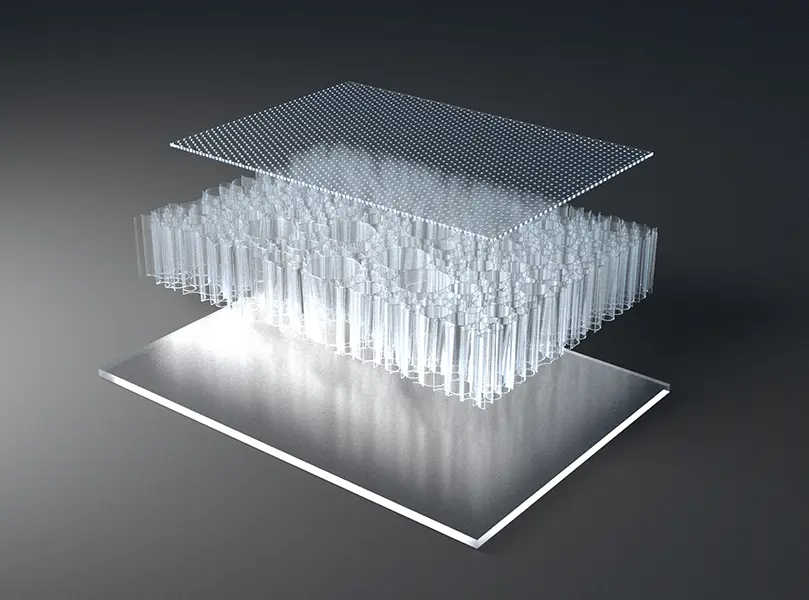

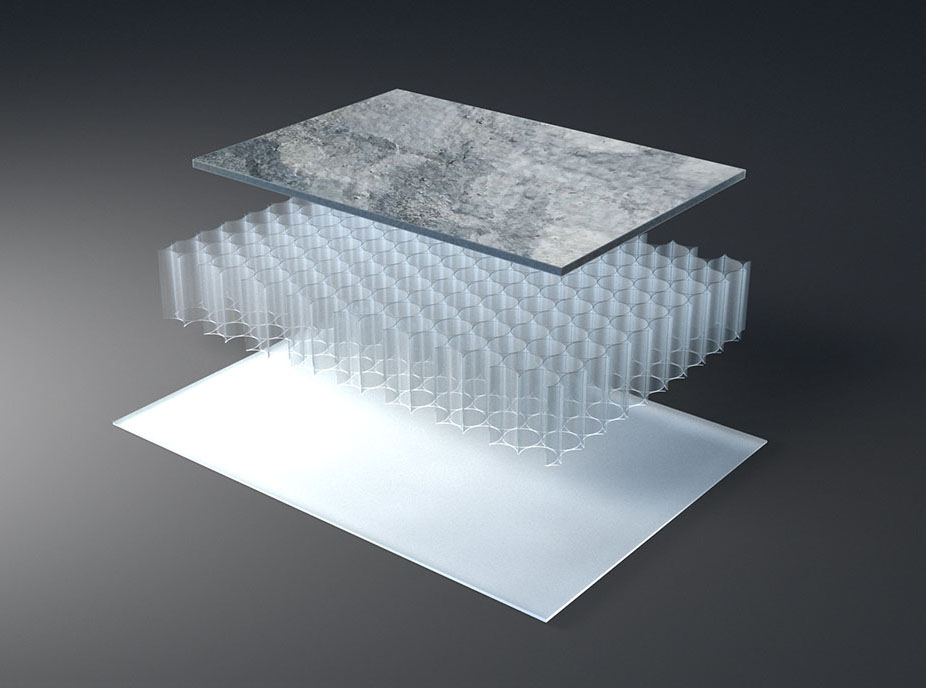

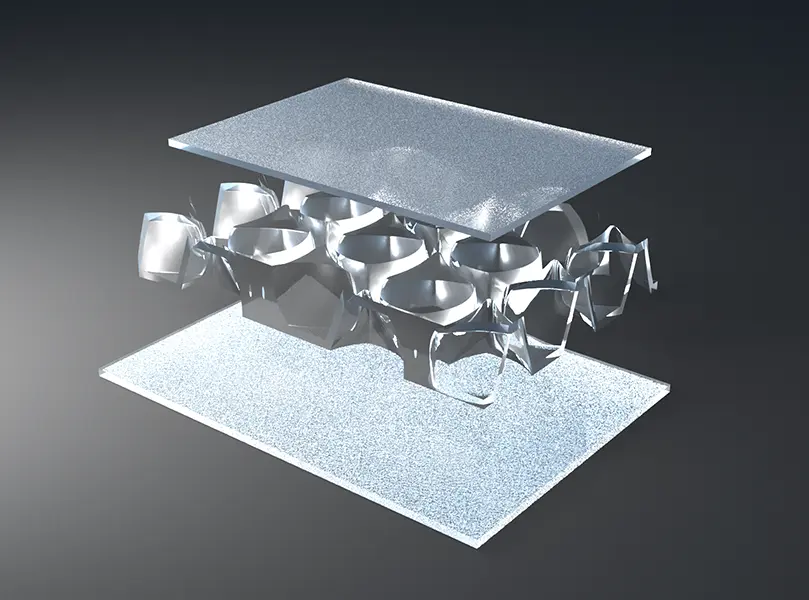

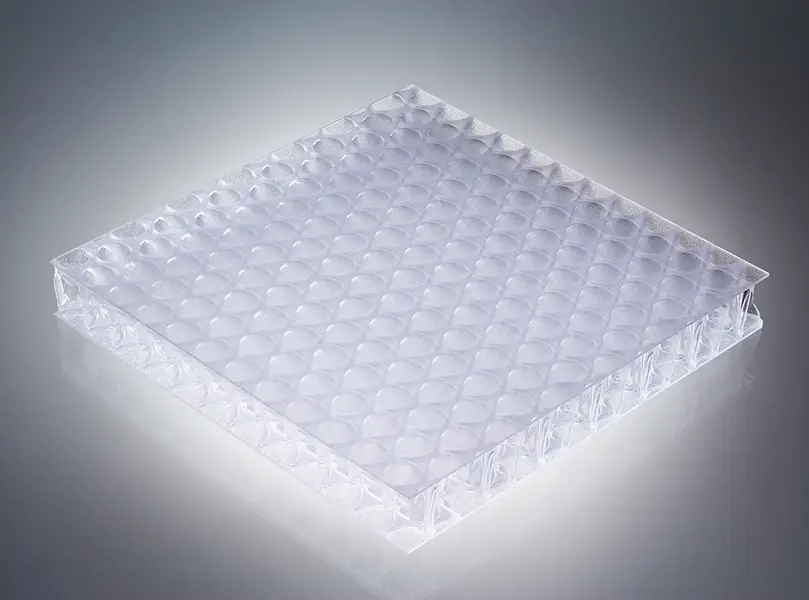

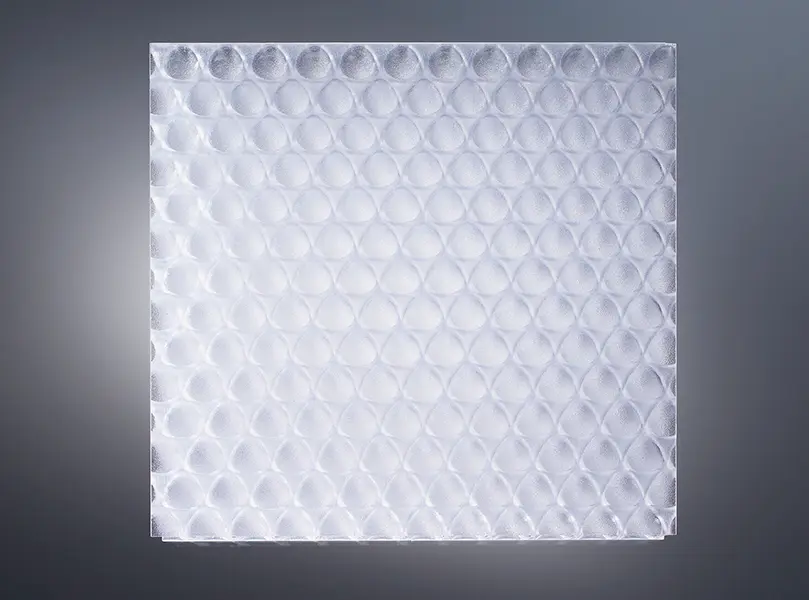

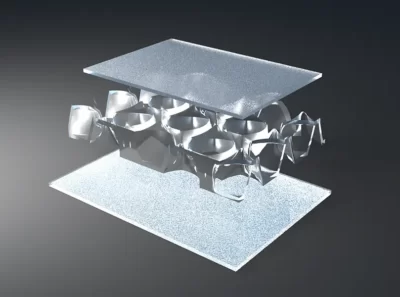

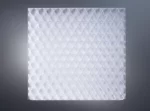

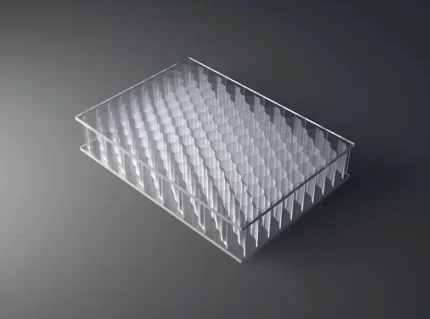

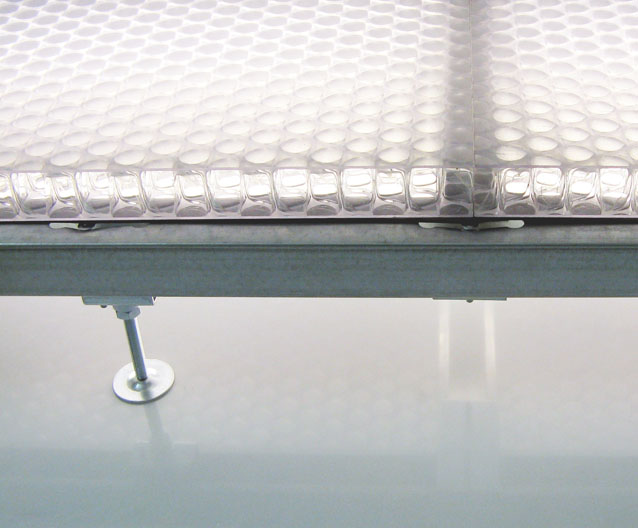

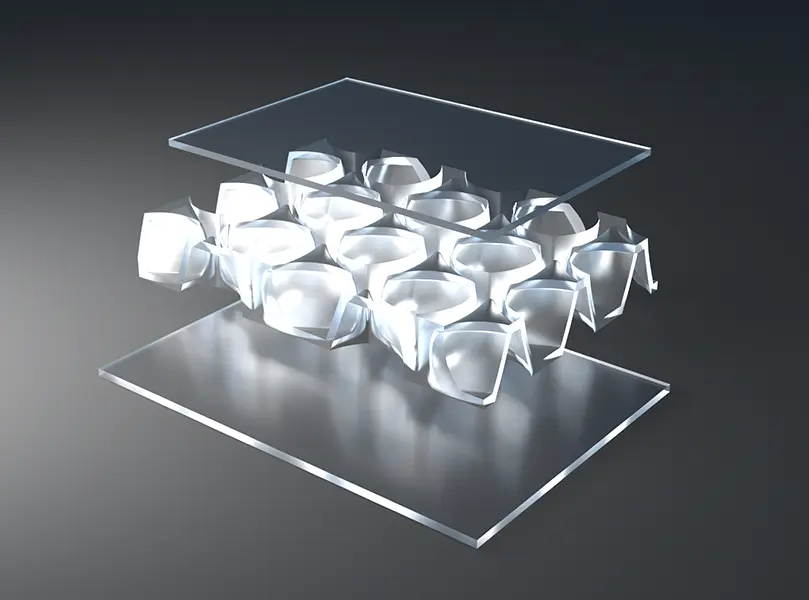

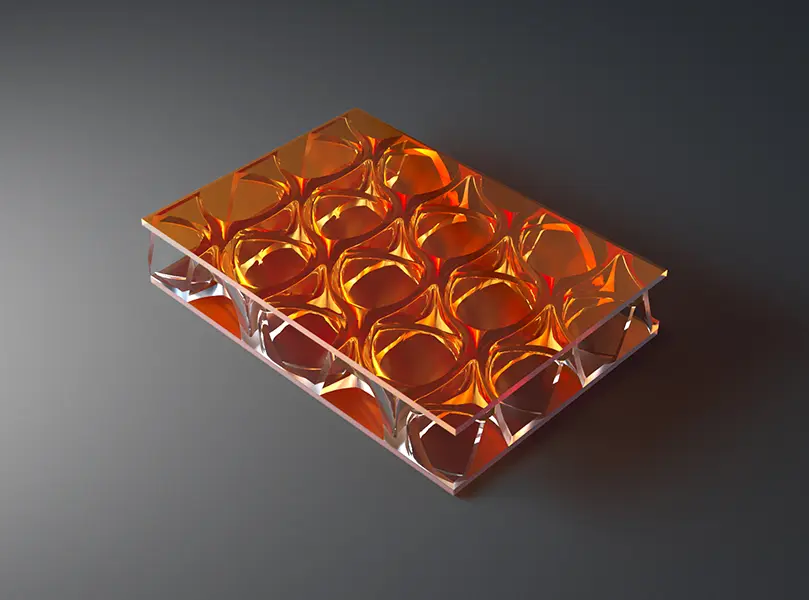

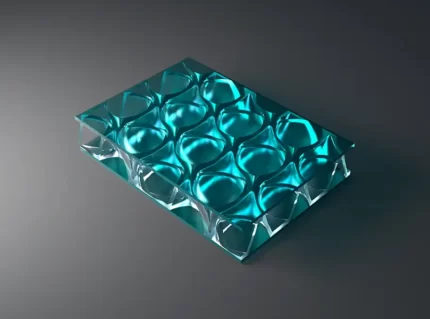

clear-PEP® ECO PC stage honeycomb panels are made with our patented polycarbonate TRIcore, made with our specially designed core expander. The innovative characteristics of the special cell structure give the lightweight panels unique visual depth but also high rigidity. PC ECO is the facing layers and has a bio-circular material content and low CO2 footprint. Normally manufactured using fossil fuels, these components have been replaced by bio-based renewable raw materials. The attributed share is up to 83% of the total material content. In addition, clear-PEP® ECO PC stage is 100% recyclable. These lightweight panels combined with different options can be used in many different ways in interior and exterior architecture to suit the needs of your design. Visit the Resources section for edge finishing and other options.

Full fabrication services are available and hardware integration resources may be available.

The following options are also available:

| Digital printing for indoor use: clear-PEP® ECO PC stage printed (*) |

Special UV Resistant coating for outdoor use: clear-PEP® ECO PC stage coated (*) |

* Requires RAL color number. RAL colors are converted to translucent colors and will vary from the actual RAL color.

There is no MOQ, a set-up fee may apply.

DIMENSIONS

| Format | Length [mm/inches] | Width [mm/inches] | Thickness [mm/inches] |

|---|---|---|---|

| Standard | 2,000/78.75 | 1,000/39.3 | 40/1.57 |

| Special Dimensions* | max. 3,000/118.11 | max. 1,220/48.03 | max. 40/1.57 |

| Production/Cutting Tolerance | 2/-2 to 0.08/-0.08 | 1/-2 to 0.04/-0.08 | 0/-1 to 0/-0.04 |

*on request – minimum orders apply

PHYSICAL PROPERTIES

| Product | Coefficient of Thermal Expansion acc. to DIN 537522-A [1/K] |

Service temperature [C/F] | G Value (total energy transmission value) based on solar angle | Facing Sheets | * Estimated Light Transmission [%] |

|---|---|---|---|---|---|

| clear-PEP® ECO PC stage | 6.5 x 10-5 | -30 to +80 / -22 to 176 | 0.62 (0o), 0.58 (30o), 0.55 (45o), 0.43 (60o) | 2mm UV PC textured | 47% |

* estimated using standard thickness of 40 mm / 1.57″

MECHANICAL PROPERTIES

| Thickness [mm/inches] |

Weight per unit area [kg/m2/lbs/sqft] |

Thermal insulation U-value [W/M2K] |

Sound insulation RW [DB] |

*Modulus of Elasticity [N/MM 2] |

|---|---|---|---|---|

| 30/1.18 | 9.7/1.98 | 2.4 | 25 | 1,688 |

| 40/1.57 | 9.7/1.98 | 2.1 | 25 | 2,933 |

*per 1m panel width

Deflection* caused by self-weight

| Product | Thickness | Support distance 600mm [23.26″] [mm / inch] |

Support distance 1000mm [39.37″] [mm / inch] |

Support distance 1200mm [47.24″] [mm / inch] |

|---|---|---|---|---|

| clear-PEP® ECO PC stage | 40mm (1.57″) | 0.1 / 0.0041 | 0.3 / 0.0123 | 0.6 / 0.0246 |

*… supported at two edges

Deflection* under a load of 1000N/m2 (20.88 psf)

| Product | Thickness | Support distance 600mm [23.26″] [mm / inch] |

Support distance 1000mm [39.37″] [mm / inch] |

Support distance 1200mm [47.24″] [mm / inch] |

|---|---|---|---|---|

| clear-PEP® ECO PC stage | 40mm (1.57″) | 0.5 / 0.0205 | 3.5 / 0.1434 | 7.2 / 0.2951 |

*… supported at two edges

Load Values

| Support centers 500mm | Support centers 750mm | Support centers 1,000mm | ||||

|---|---|---|---|---|---|---|

| Thickness in mm | 30 | 40 | 30 | 40 | 30 | 40 |

| Deflection in mm, support on 2 sides | ||||||

| Applied load 2500 N/m² | 1,0 | 0,6 | 4,7 | 2,6 | 14,5 | 8,1 |

| Applied load 3500 N/m² | 1,4 | 0,8 | 6,6 | 3,7 | – | 11,3 |

| Applied load 5000 N/m² | 2,0 | 1,1 | 9,4 | 5,3 | – | – |

| Deflection in mm, support on 4 sides | ||||||

| Applied load 2500 N/m² | 0,6 | 0,5 | 1,9 | 1,1 | 4,3 | 2,5 |

| Applied load 3500 N/m² | 0,8 | 0,5 | 2,6 | 1,5 | 6,0 | 3,4 |

| Applied load 5000 N/m² | 1,2 | 0,7 | 3,8 | 2,2 | 8,6 | 4,9 |

FIRE CLASSIFICATION

| Fire Classification | ASTM D-2843 Smoke Density [%] |

ASTM D-635 Burning Rate [inches] |

ASTM D-1929 Self Ignition Temp. [F] |

ASTM E648-17/NFPA253 WATTS/CM2 |

|---|---|---|---|---|

| C1/CC1 | 53.30% | <1″ | 1093 | >1.10 |

POPULAR APPLICATIONS

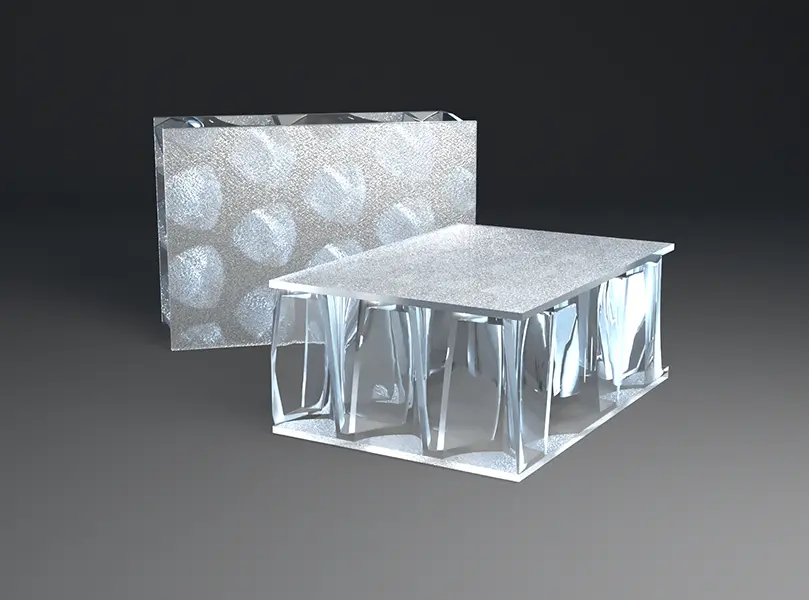

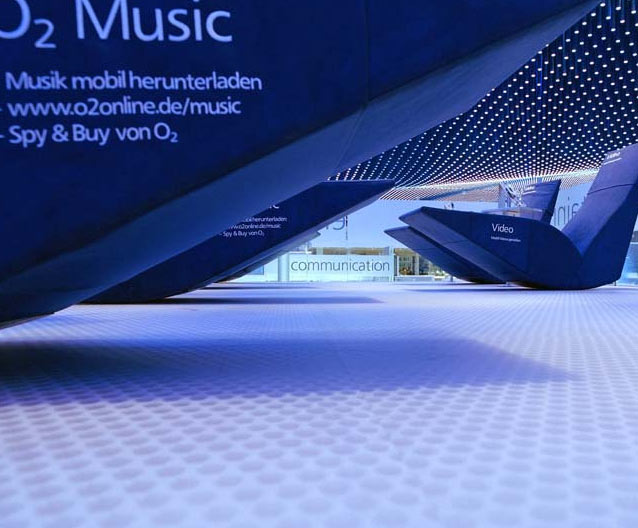

Particularly suitable as a backlit floor panel (also for stages, platforms, exhibition floors) or as a walkable cover.

All information and specifications contained herein are based on the most up-to-date information available and to the best of our knowledge. These specifications are subject to change at any time. A legally binding assurance of certain properties or the suitability of an individual type for a specific field or application cannot be inferred from these specifications. All information is provided without any obligation. No legal liability can or will be assumed.